1994 Nordlund Custom MY

Yacht price: $395,000

- Overview

- Specifications

- Gallery

- Descriptions

Overview

MAJOR PRICE REDUCTION OF $100,000CALL ASAPORIGINAL OWNERBEAUTIFUL CUSTOM YACHTBRING ALL OFFERSRecently had a $43,000, 1000 hour service!

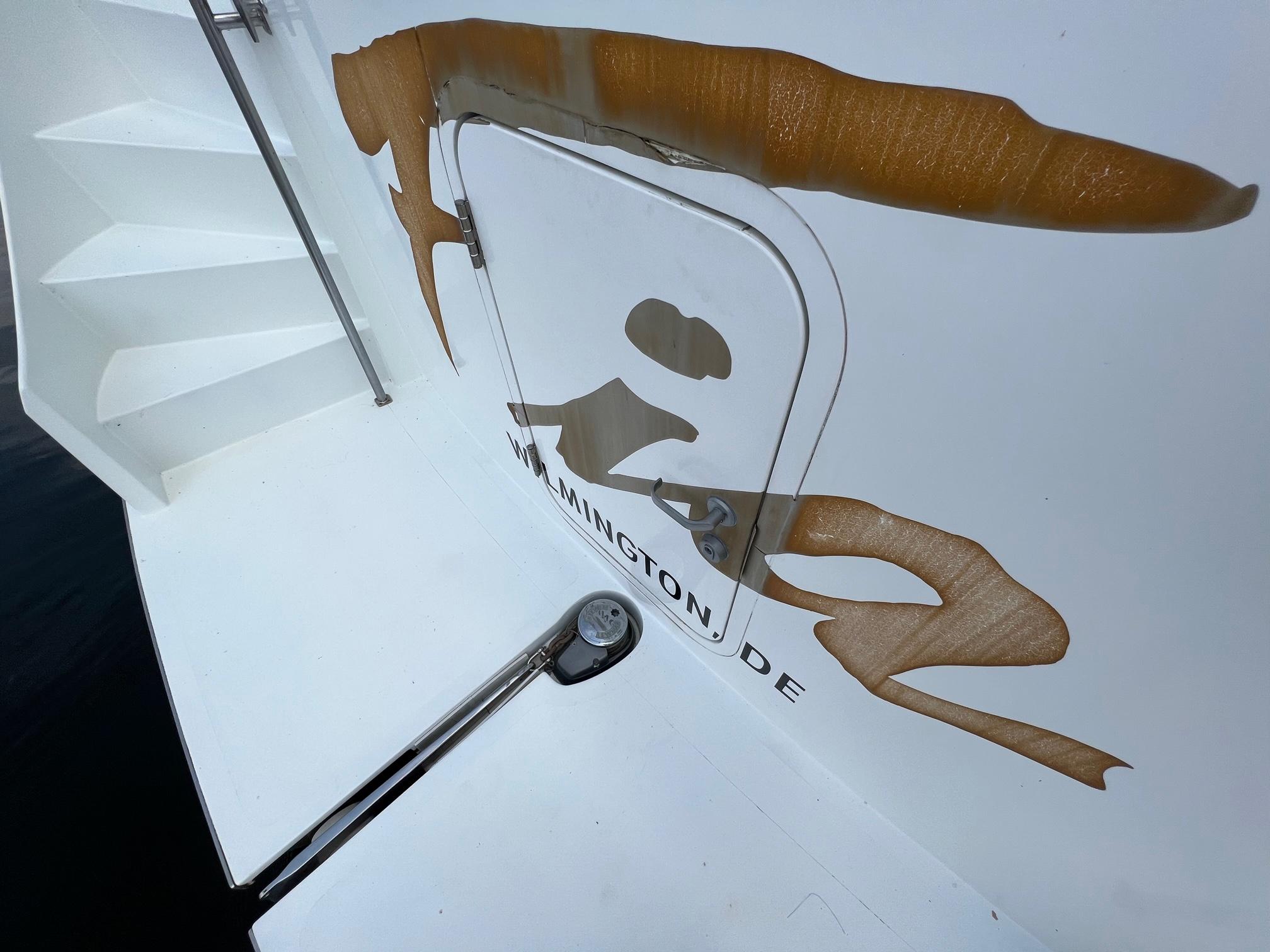

Original Engine Hours: 1050 hrs Generator Hours: 300 hrs

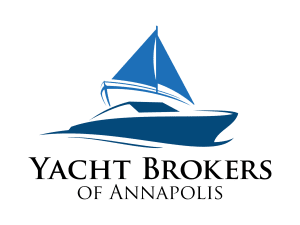

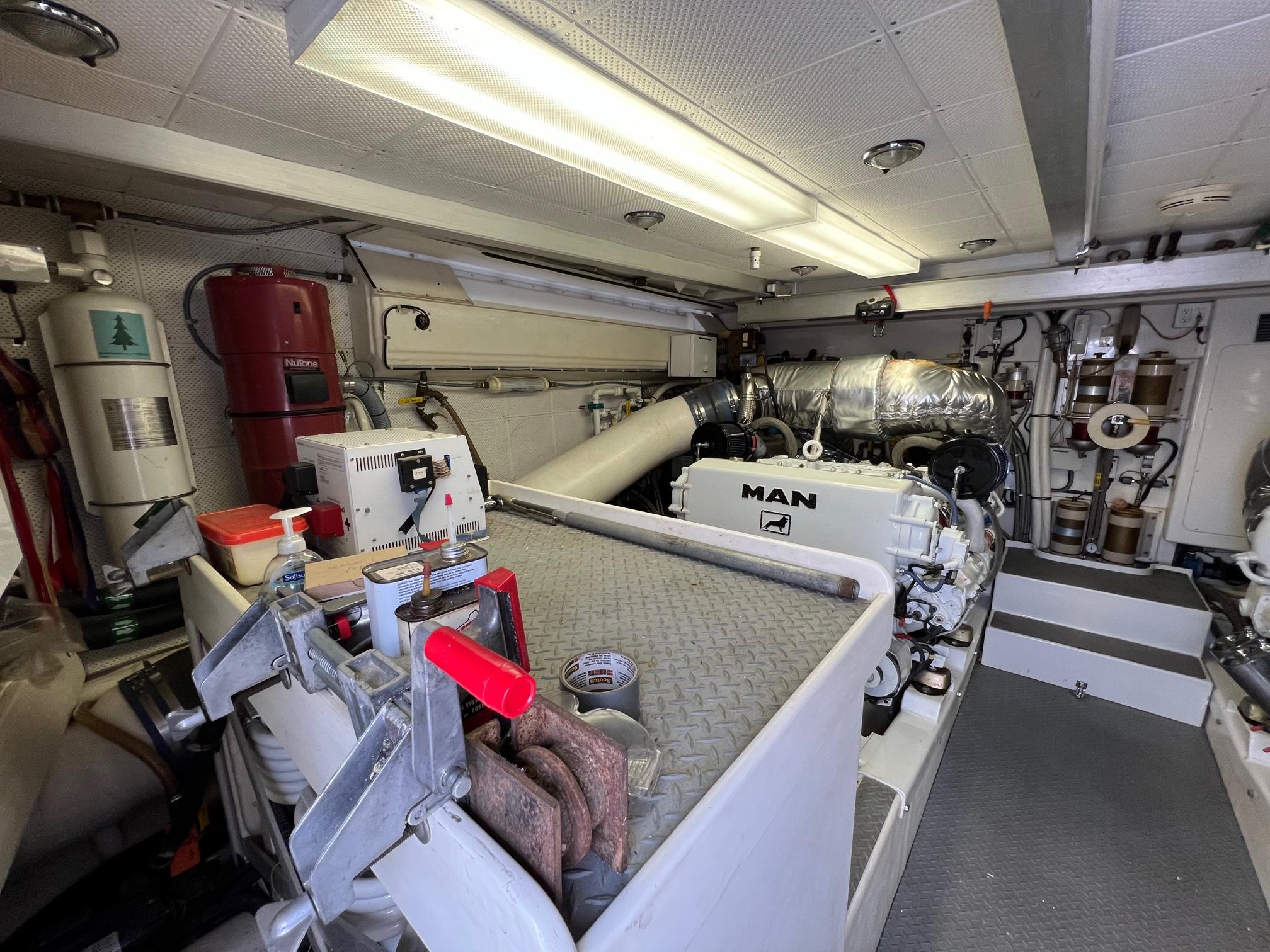

Welcome aboard this 1995 Custom Built 65 Nordlund "FIA". She is powered by Twin Diesel MAN engines, which coupled with her continuous upgrades and generous layout, makes for a comfortable and reliable yacht for live aboard or extended family or guest trips. This vessel is a keel up custom build and has been garage kept in fresh water since her christening. "FIA" is located in Earlville, MD.

Specifications

Basic Information

- Manufacturer:

- Nordlund

- Model:

- Custom MY

- Year:

- 1994

- Category:

- Power

- Condition:

- Used

- Location:

- Annapolis, MD, US

- Vessel Name:

- FIA

- Boat Type:

- Flybridge, Motor Yachts

- Hull Material:

- Fiberglass

- Designer:

Dimensions & Weight

- Length:

- 63 ft - 19.2 meter

- LOA:

- 63 ft - 19.2 meter

- Beam:

- 63 ft - 19.2 meter

- Draft - max:

- 4 ft - 1.22 meter

Engine

- Make:

- MAN

- Model:

- V-8 D28482XE

- Engine(s):

- 2

- Hours:

- 1037

- Engine Type:

- Inboard

- Drive Type:

- Direct

- Fuel Type:

- Diesel

- Horsepower:

- 850 (Individual), 1700 (combined)

Tank Capacities

- Fuel Tank:

- 851 Gallon(s) - 1 tank(s)

- Fresh Water Tank:

- 187 Gallon(s) - 1 tank(s)

- Holding Tank:

- 80 Gallon(s)

Accommodations

- Total Berths:

- -

Gallery

Descriptions

Vessel Features

"FIA" offers both comfort and convenience, see below a few of her features:

Vessel Accommodations

3 Staterooms. Each stateroom has a "Head" (bathroom) with American Standard Stall Shower, Macerator Toilet, and Sinks mounted in a Vanity storage cabinet. 1) Master Stateroom: Full beam width. Queen Bed. ("Sleep Number" type mattress.) Concealed Entertainment Center, Make Up desk, voluminous Cedar lined closets and large storage drawers. 2) Guest Stateroom: Full beam width. Queen Bed. Make Up desk, voluminous Cedar lined closets and large storage drawers. House size Washer and separate house size 240 Volt Dryer are concealed in a cabinet. 3) V-Berth Stateroom: 2 Cedar lined closets. Designed with plans drawn for a V Berth installation. Currently used as a Gym with a removable Center Stack Weight Station to enable easy conversion to a V-berth.Navigation

- Auto Pilot: Robertson AP300X (2)

- Hand held remote steering (2)

- Power Steering: Hynautic Hydraulic 3 ½ turns "lock to lock"

- Plotters & Radar: (2: Wheelhouse and Fly bridge)

- 2-Ray-Marine E120/W Hypertouch Plotters with Radar. (Wheelhouse and Fly bridge). 25-mile range Radar

for close in navigating detail - (Radom on radar arch is hinged for lowering if required.) - Ray-Chart 610T and Ray Chart 611T Wheelhouse In-op

- ICOM-IC-M126 DDSC VHF (Wheelhouse)

- HORIZON INTREPID VHF (Fly bridge)

- Ritchie Digital with Auto Pilot Control (2)

- Rudder Position Indicator: Data Line X

- Depth Sounder: Cetrek (2)

- Engines: 2-MAN V-8 D28482XE Diesels 850 hp.

- Hours:1037 Starboard & 1033 Port (7/4/22)

- Piston upgrade has been performed

- Oil Cooler upgrade has been performed

- Block Heaters: Kim Hotstart

- Generator: Northern Lights M844 16 KW 293 hours (7/4/22)

- Transmissions: Twin Disc MG 5111V with Trolling Valves. Custom welded on aligning system insures easy, perfect alignment between engine and transmission

- Lasdrop shaft seals with internal spare seals

- Under the aft deck 6’-5” head room. It is accessible from the swim platform as well as from an interior companionway.

- ½ Ton Rolling Beam Crane is mounted to the engine room ceiling aluminum I-beams. I-beams are spaced to allow engines to be removed intact up to the aft deck.

- Generator

- Spare Strut. Ambidextrous, fits Port or Starboard

- Spare Propellers.

- Batteries

- Spare 3”SS shaft. Double tapered. Machined to fit both engine(s) female tapered couplings

- 3 station engine and transmission controls: Wheelhouse, Fly–bridge and Aft deck.

- Wesmar 24v. 2 stations. Both operated by rubber covered marine foot switches. This leaves both hands free to operate throttles and clutches.

- Engine Start and House Battery parallel switch. Power steering. 3 ½ turns lock to lock.

- There is a stand-by, Morse single lever cable control for throttle and transmission. Located under the wheelhouse helm console, the cables terminate in the engine room. Can be used as a “get home” control in the rare event one of the electronic controls fails.

- Electric Pump Out Crankcase oil drain and Refill system.

- Oil filter drain “plugs” has been replaced with lockable ball valves to easily drain and completely empty out filters prior to filter change.

- In the event of an “engine out”, the “Operating Engine” is plumbed to supply water to the shaft seal on the “Engine Out”.

Shore Power Inlets:

3 inlets for 50 amps, 240 volts:

- Bow is one standard 50 Amp,240 Volt marine waterproof inlet

- Stern inlets: 2 Cablemasters. Each 50 foot cords, 240 Volt, 50 Amp. One Port, One Starboard.

- Secondary Stern Inlets: 1 Port and 1 Starboard standard 30 Amp, 240 Volt, waterproof inlets.

- 2 - (1 Port, 1 Starboard) 240 volt, C-Power isolation transformers. This allows the boat to use its full compliment of electrical draw using just 50 amps.

Inverter:

- One Trace 2000 Watt Inverter

Telephone/TV inlets:

- Port and Starboard located at stern

- Approximately 851 gallons total in 2 tanks. One under Master bed and one under Guest bed.

- The tank tops are recessed below the sides to form a “well” on the top of the tank. The well size has been calculated to hold all the fuel in the fill hose in case the hose should ever leak at the connection, and is easily accessible to pump out. Without this, the leakage and it’s odor, would spill into the bilge.

- Two selectable Racor filters for each engine. Water alarms are on each filter with notification to boat’s Alarm System.

- Racor drain “plugs” have been replaced with ball valves (safety wired shut) in order to easily drain off any accumulated water or empty out prior to filter change.

- Fuel manifold has selector valves, and an electric pump to prime the filters at filter change.

- Both Fuel tanks can be pumped out from valve connections in the engine room.

- All fuel lines in the bilge run in separate fiberglass lined troughs.

- Fuel (and water) measurements are done with a “Tank Tender” gauge.

ENGINES:

- Low Oil Pressure

- High Temperature

- Heat Exchanger Raw Water Flow Loss @ Exhaust Pipe

- Coolant Water Level Low

- Drive Oil Pressure

- Drive Oil Temperature

- Smoke

- Heat Rate of Rise (Shuts engine room vents, releases flame retardant)

- Smoke

- Gym

- Guest Stateroom

- Master Stateroom

- Engine Room

FUEL AND WATER: Each tank is selectable. Audible alarm sounds when tank is approximately 8 gallons from the top.

FUEL FILTERS (Racor): "Water in fuel"

"INTRUSIAN /BURGULAR".

Sensors: P& S and Aft deck. This is a Residential unit.Bilge and Emergency Pumping

24 Volt:

There are 4 pumps: One in each bulk headed section of the bilge between the bow and the engine room. They are activated by magnetic switches and include separate contacts for the alarm system. Pumps can also be manually started from the helm station.

120 Volt high capacity:

There are 4 pumps: One in each bulk headed section of the bilge between the bow and the engine room. They are are activated by a sealed diaphragm switch. They can also be manually activated at the pump site.

The 24 and 120-volt pumps are set to operate in series with the 24-volt coming on first.

Groco SBV emergency seacocks:

Engines and generator have the option of being used as EMERGENCY BILGE PUMPS. Merely close the connected GROCO SBV seacock valve, and then remove a plug to pump out the bilge waterHeating and Cooling System

Cooling:

Marine Air Hydronics Chilled Water System with individually controlled air handlers and thermostats in the Engine Room, Each Stateroom, V Berth/Gym, Salon, Galley, and Wheelhouse.

Heating:

Built in Hot Water Heating System throughout the vessel with individual thermostats in each Stateroom, V Berth/Gym, Salon, Galley, and Wheelhouse.

Heat from the refrigerator can also be vented inside in the Winter, or outside in Summer.

With the aft deck enclosure in place in the winter, the temperature out there can reach 75 degrees on a 35-degree day. A temperature-controlled fan in the aft deck bulkhead can bring this hot air in to warm the main salon if using the baseboard heat is not necessaryPlumbing System

Drinking Water: Dedicated General Ecology Filtration System. Filters taste, odor, and water down to ½ Micron. Removes Giardia, Cryptosporidium, etc., and removes bacterial and Viruses instantly without the addition of chemicals, electricity or wait time. Fill the water tanks at any marina without concern!

Hot water re-circulation system provides push-button instant hot water in the Master shower and sinks, as well as the Galley sink. No precious tank water is wasted down the drain waiting for the hot water to arrive!

187 gallon 316L Stainless Steel water tank.

Push-button operated tank fill valve with safety overflow. Audible alarm sounds when tank is within 8 gallons of full.

2- 10 gallon 240 volt water heaters. Valves and couplings allow for single tank use, tandem use, or series use. Either tank can removed easily for service without affecting the other tank or water system.

One- 240 volt “Well” Water pump and One- 24 volt marine water pump. Pumps are set to automatically switch from 240 volt power to 24 volt power when shore power is disconnected. If generator power is used, pump will switch back to 240 volt. All of this is easily changeable.

Hot and Cold water is ultimately directed throughout the boat from 2 manifolds in the engine room. Each spigot in the boat is a “home run “ from the manifold. Therefor, any individual valve(s) can be shut off for service at the manifold without affecting the balance of the system. Also, any faucet and supply can be winterized individually.

Raritan electric macerator heads with remote pumps for easy servicing.

One forward head is optionally plumbed for fresh water operation

Head Discharge: Discharge is individually directed to either “Overboard”, or “Holding Tank”. This is done with individual electric motor valves for each head. Each valve can be selected, and then key locked at the Main electric panel in accordance with USCG.

All plumbing connections on the boat are easily acceptable. They are either wall mounted or have access panels.

There is an anchor wash down fitting and interior plumbing installed on the bow. Currently not in use.

All plumbing (except Heads) drains into a main drain system (P & S) running Fore and Aft and exits out the transom at the exhaust opening. NO ugly thru hull fittings on the sides of the boat!

High-pressure, Stainless-steel piping, boat washing system with “Soap” or “Rinse” options. Bow, stern and aft deck controls and high-pressure water connections. (Note: All plumbing and electric controls are in place and ready to go. The pump has never been installed.) This system is similar to a car wash system.Disclaimer

The Company offers the details of this vessel in good faith but cannot guarantee or warrant the accuracy of this information nor warrant the condition of the vessel. A buyer should instruct his agents, or his surveyors, to investigate such details as the buyer desires validated. This vessel is offered subject to prior sale, price change, or withdrawal without notice.

Watch Video:

-

1995 Nordlund 65