Well, we finally started part II of the big floor overhaul last weekend. It certainly took us a while to get here, mostly because we were trying to figure out the best way to proceed. You may have recalled our first post when we discovered that a hose coming from our fresh water tank was cracked as well as condensate drains had been leaking water into the area of the floor in between the fiberglass and balsa core. FOR YEARS. When we cut out a small section for inspection, we saw that it looked like a lake under there – much worse than we had anticipated. We ended up ripping out a 6×8 section – nearly half the salon floor down to bare fiberglass.

Yes, we’ve been living with 1/2 a floor for over 2 months. It was time for a little action. Christmas is approaching and this was at the top of my Wish List.

The first step was figuring out the best way to adhere the remaining wood floor to the fiberglass. There was about a 1/4? gap between the two that we wanted to seal to make sure it was rock solid. We were wondering why the floor seemed a little bouncy when we sea trialed the boat for our survey. I’m guessing this is why…. The huge gap between the hull and flooring, coupled with wet balsa made it feel like a moon bounce!

We drilled holes about every 4? thru the wood floor and just into the fiberglass. One slip of the drill and we would suddenly have additional water views – and not in a good way! To think that there has only been less than two inches of flooring all this time was a little unnerving!

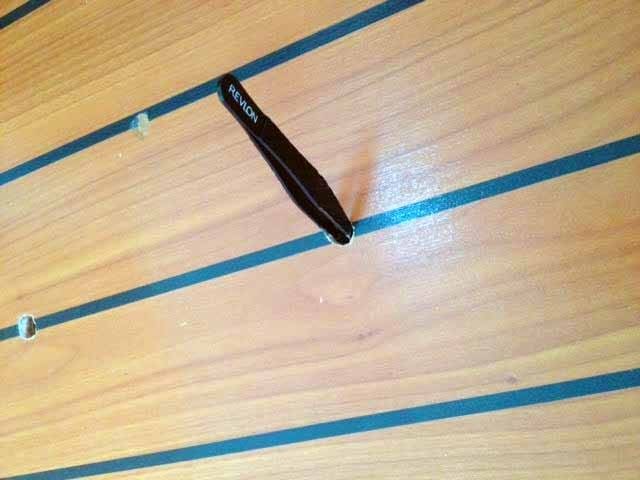

The thing with all of those holes? The vacuum didn’t get all of the debris from the drill so I had to pick out and remaining shavings with an old set of tweezers. We’re just finding new uses for old things all over the place!

After the holes were drilled, that’s when the real work started… mixing all of the epoxy. So.Much.Expoy. We would mix a batch, pour it into a disposable caulk tube, and pump it into each and every hole. (The mixture would harden within minutes, so we couldn’t reuse anything). Then we ran a flat edge over the floor to smooth the extra epoxy overflowing from the holes to avoid having to sand each hole in the next phase.

Matt was going thru the mixture quicker than I could mix up a new batch. 11 pumps epoxy, 11 pumps hardener, 5 scoops high density filler. Repeat. Over and over again. I’m not gonna lie – I was definitely channeling my inner Walter White while I was stirring away. How easy would it be to sail 10 miles off shore, drop anchor, and mix up a batch of whatever? I’m sure it’s already happening. Funny how you need to jump through hoops just to purchase a box of Sudafed, but you can buy a 5 gallon jug of toxic epoxy without so much as a bat of an eye. Hmmm…

At least I had the best view in town as I was mixing away. Ah, the highs and the lows of living on a boat. Ha!

Sorry for the blurry pics. This process took us several hours to complete, and we were slowly loosing the will to live. Plus, I think the fumes were a bit stronger than we realized.

We put our life raft and a battery on the floor to weight it down – combined they were over 100lbs – and to ensure maximum contact.

Because the first time wasn’t fun enough, The next day Matt decided to add a few more holes so the next day we got to do it all over again!

I’m thinking Phase II was a success… SOLID!

Around 9pm the first night after all day of epoxy mixing I was on a roll, I got a hair up my @$ and decided to scrub the fiberglass floor. It looked so gross, but I didn’t know if it was dirty, or if the fiberglass was just super stained. Full disclosure: it was just dirty. Here is an in process pic. Can you see where I cleaned and where I didn’t?

Don’t judge, Mom.

So, Matt and I busted our butts on Phase II. Looks like we’ll have to look into getting some better help for Phase III. These girls just couldn’t keep up!